Isanti ye-quartz yeyona nto ibalulekileyo kwimizi-mveliso yeeminerali ekrwada, impahla engeyiyo imichiza eyingozi,oko ikukuthiisetyenziswa ngokubanzi kwiglasi, ukuphosa, iiseramics&izinto zokuchasa, ukunyibilikisa i-ferrosilicon, i-metallurgical flux, i-metallurgy, ulwakhiwo, ishishini lemichiza, iiplastiki, irabha, i-abrasives kunye namanye amashishini.al imathiriyeli.Isanti yequartz ngokuqhelekileyo luhlobo lwemathiriyeli yokucoca amanzi eyenziwe ngentsimbi yendalo yequartz, ecunyuziweyo, ihlanjwe, yomiswe kwaye ihlolwe kabini.

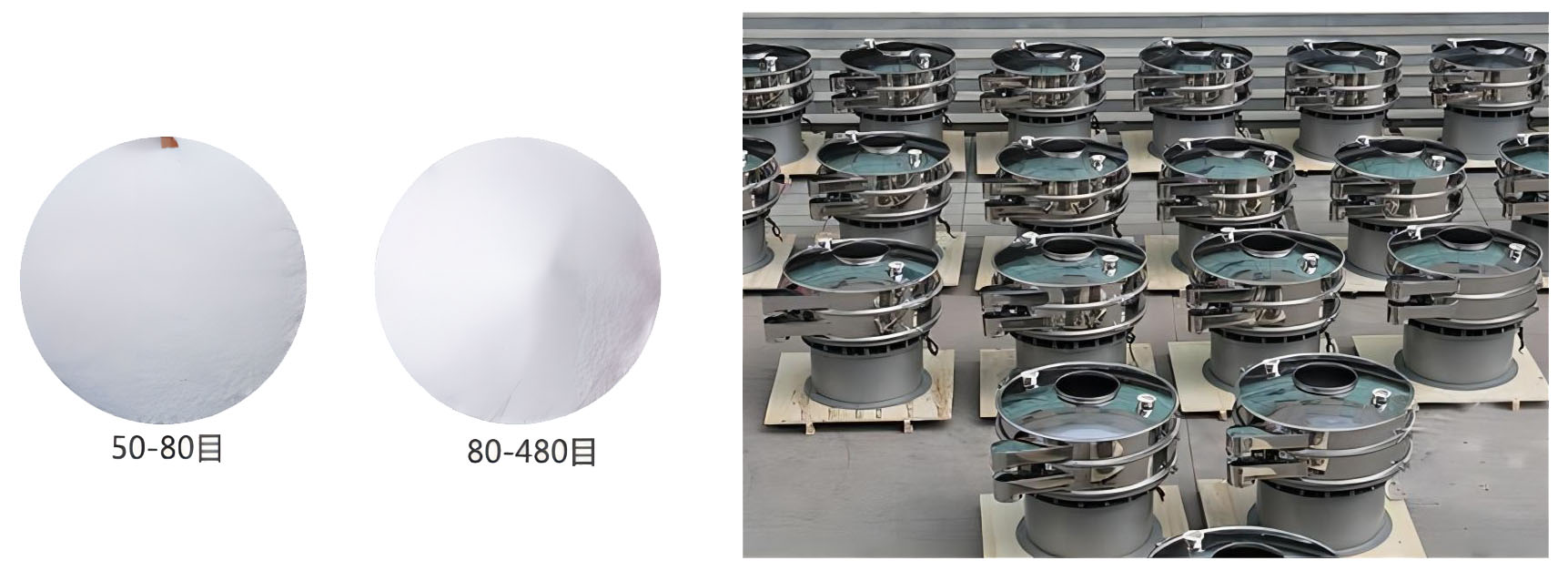

Imveliso eyomileyo yesanti ye-quartz, izixhobo eziphambiliisikrini esingcangcazelayongenxaisanti yequartz, umatshini wokunkqonkqoza amatye, i-crusher njalo njalo.Inkqubo yetekhnoloji yeyokuba ilitye lelitye le-quartz licutshungulwa libe ngamatye amancinci ngomatshini wokunkqonkqoza ilitye, ilitye licutshungulwa yi-pulverizer, kwaye emva koko.ihluzwe ngu aukungcangcazela kwesikrini .Kwinkqubo yokuhlola, intsimbi iyasuswa ngokusebenzisa ibha yemagnethi kunye nemagnethi, kwaye ke ukupakishwa kugqityiwe kwaye kufakwe kwindawo yokugcina.

Inkqubo yokuvelisa isanti yequartz

1.Umatshini orhabaxa: (ngokubanzi i-1-0.5mm, 0.5-0.1mm ingalungiswa)

Khetha imigodi yesanti ye-quartz enomgangatho olungileyo wemigodi yokuqala;isanti ye-quartz egayiweyo iqala ukutyunyuzwa ngesityuli somhlathi, kwaye izinto ezityumkileyo zihanjiswa kwiumgca wokungcangcazela kwesikriniukukhangela okuphambili ngokusebenzisa i-belt conveyor, kunye neengqungquthela ezinkulu zibuyiselwa emihlathini.I-crusher isetyenziselwa ukutyunyuzwa kwesibini, kwaye iincinci ezincinci zihanjiswa ngumqhubi webhanti kwi-roller crusher yokutyumza okwesibini.Isanti ye-quartz echithwe yi-roller crusher ithunyelwa kwi-screening ecocekileyoumgca wokungcangcazela kwesikrinikuhluzo kunye nokuhlelwa.

2.Ukuqhubekeka kakuhle: (50-480 mesh)

Isanti yequartz esekwe ngokurhabaxa ye-1-0.5mm kunye ne-0.5-0.1mm yamabanga inokushukuma kwaye iculwe yi-vibrating mill / vibrating rod mill.Emva kokusila, inokuhluzwa ngeisikrini se-ultrasonic vibrating okanye i-quartz yesanti yokungcangcazela kwesikrini ukulungiselela i-100 -300 mesh powder fine;ukuba ufuna ukufezekisa ukugaya okucokisekileyo, i-Raymond mill esebenza ngokufanelekileyo isetyenziselwa ukucola, kwaye akukho mfuneko yokusefa umgubo.Indawo yokusila iRaymond ixhotyiswe ngokubanzi ngesihlalutyi.Beka umbandelakwi-analyzer yebakala eligqityiweyo ukulungiselela i-300-500 ye-mesh egqityiweyo iimveliso.

Isikrini sokungcangcazela kwesanti yequartz luhlobo oluqhelekileyoisikrini esijikelezayo sokungcangcazela izixhobo.Yeyezixhobo zokususa ukungcola okukhanyayo.Ingasetyenziselwa kwi-1-5 imigangatho ngexesha elinye.Isixhobo sineempawu zobukhulu obuncinci,encinciisithubaumsebenzi e, ingxolo ephantsi, ukusebenza kakuhle, ukuguqulwa kwesikrini esifanelekileyo, isakhiwo esivaliweyo ngokupheleleyo, njl.Isetyenziswa ngokubanzi kwi-0-400 mesh eyomileyo, emanzi, ecocekileyo, erhabaxa,ukukhanya kwaye kunzimaumgubo,kunye ne-granules zinokujongwa ngokulula, kunye ne-0-600 ye-mesh slurry materials inokucocwa ngokulula.

Umgaqo osebenzayo wesikrini sokungcangcazela kwesanti yequartz:

Isikrini sokungcangcazela sesanti yequartz sisebenzisa imotor yokungcangcazela ethe nkqo njengomthombo wovuselelo, kwaye intshukumo ejikelezayo iguqulwa ibe sisinyanzelo esithe tye, esithe nkqo kwaye sithambekele esine-dimensional ye-eccentric kumaphelo aphezulu nasezantsi emoto yokungcangcazela, kwaye idluliselwaumphezulu wekhusi weisikrini esijikelezayo sokungcangcazela; Faka izixhobo ngezibuko lokutyisa.Ngokweemfuno zokuhlola izinto ezahlukeneyo, izixhobo zihlolwe ngoluhlu lwe-1-5 lwezikrini ezilukiweyo zetsimbi ezinamanani ahlukeneyo e-mesh.Ngethuba le nkqubo, ibhola ye-silicone yokuphosangenxaUkucoca phantsi kwezikrini zomaleko ngamnye ngokuqhubekayo kubetha isikrini ngokungcangcazela rhoqo, ukuze izinto ezikumaleko ongaphezulu kwesikrini zinokujongwa ngokutyibilikayo kwiscreen, kwaye zisombulule ngempumelelo ingxaki yokuthintela izinto.Emva kokuba umnatha ukhutshiwe kwindawo yokukhupha yomaleko ngamnye, injongo yokukhangela kunye nokususa ukungcola okanye ukuhluza kunye nokuhlelwa ekugqibeleni kufezekisiwe.

Ixesha lokuposa: Nov-05-2022