Ciidda Quartz waa walxo ceeriin oo warshadeed oo muhiim ah, alaab aan kiimiko ahayn oo khatar ah,taasoo ahsi ballaaran loo isticmaalo dhalooyinka, shubista, ceramics&Qalabka wax-ka-celinta, ferrosilicon dhalada, qulqulka birta, birta, dhismaha, warshadaha kiimikada, balaastikada, caag, abrasives iyo warshado kalealaabta al.Ciidda Quartz guud ahaan waa nooc ka mid ah shaandhada sifaynta biyaha ee laga sameeyay macdanta quartz dabiiciga ah, taas oo la jajabiyo, la dhaqo, la qalajiyo oo la baaro laba jeer.

Wax soo saarka qallalan ee ciidda quartz, qalabka ugu muhiimsan waashaashad gariirwaayociid quartz, mashiinka garaaca dhagaxa, burburinta iyo wixii la mid ah.Habka teknoolajiyada ayaa ah in dhagaxa quartz-ka lagu farsameeyo dhagxaan yar yar iyadoo la adeegsanayo mishiinka garaaca, dhagaxa waxaa lagu farsameeyaa pulverizer, ka dibnakala shaandheeyay ashaashadda gariir .Habka baarista, birta ayaa laga saarayaa iyadoo la isticmaalayo birta birta ah iyo magnetka, ka dibna xirmada waa la dhammeeyaa oo lagu dhejiyaa kaydinta.

Habka wax soo saarka ee ciidda quartz

1.Mashiinka qallafsan: (guud ahaan 1-0.5mm, 0.5-0.1mm waa la diyaarin karaa)

Dooro miinada ciidda quartz oo leh tayada wanaagsan ee macdanta hordhaca ah;Ciidda quartz-ka miinada ayaa marka hore lagu burburiyaa daanka, alaabta la jajabiyeyna waxaa loo gudbiyaashaashad gariir toosanbaadhista aasaasiga ah iyada oo loo marayo gudbiyaha suunka, iyo qaybo waaweyn ayaa lagu soo celiyaa daanka.Burburiyaha waxaa loo isticmaalaa burburinta labaad, qaybaha yaryarna waxaa lagu qaadaa qaadiyaha suunka oo la geeyaa rullalusha burburinta labaad.Ciidda quartz-ka ee uu burburiyay rullaluistu waxay u diraan baadhista wanaagsanshaashad gariir toosaneegida iyo kala saarista.

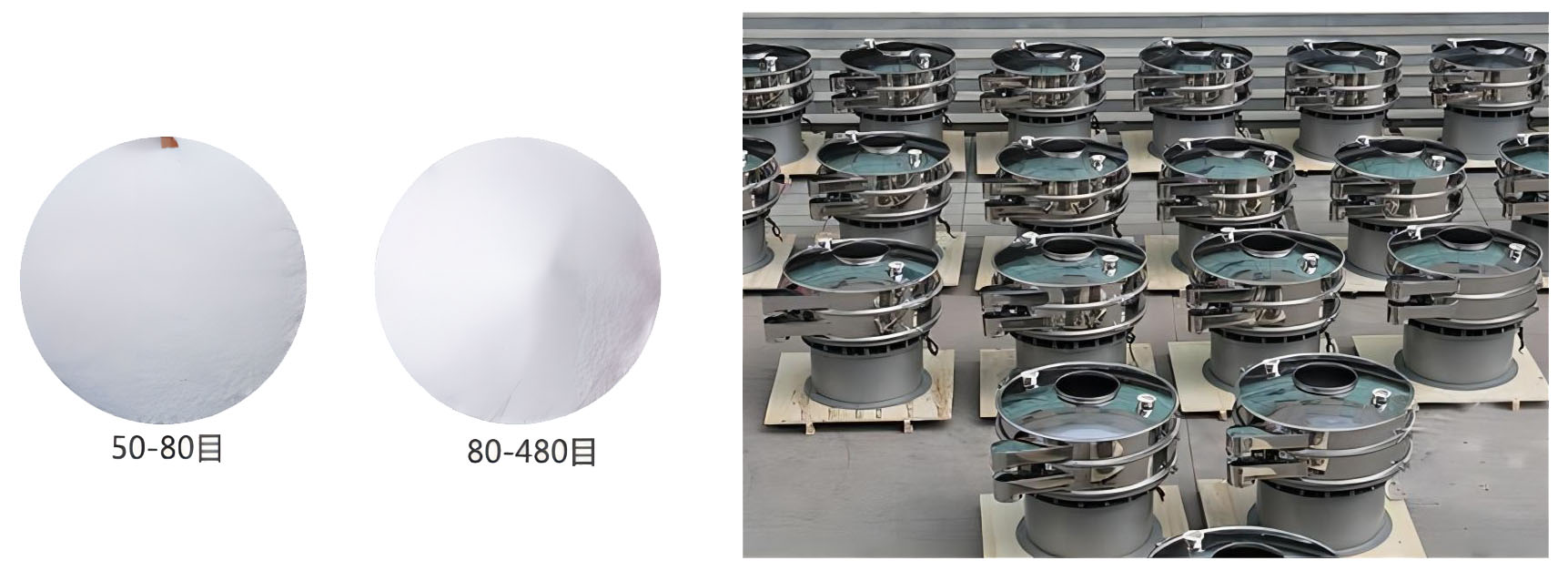

2.Habayn wanaagsan: (50-480 mesh)

Ciidda quartz ee sida aadka ah loo farsameeyay ee 1-0.5mm iyo 0.5-0.1mm darajooyinka waa la gariiray oo dhulka lagu shubi karaa mishiinka gariiraya.Ka dib marka la shiido, waa lagu shaandheyn karaashaashad gariirisa ultrasonic ama shaashad gariir ciid quartz ah si aad u diyaariso 100 -300 budo ganaax ah oo mesh ah;Haddii aad rabto in aad gaadho shiidi fiican, wax-ku-oolnimada sare ee Raymond Mill ayaa guud ahaan loo isticmaalaa shiididda, looma baahna in la shaandheeyo budada.Milkiilaha Raymond wuxuu guud ahaan ku qalabaysan yahay falanqeeye.Dhig walxahaGali falanqeeye-fasalka la dhammeeyay si aad u diyaariso 300-500 mesh badeecooyin dhammaatay.

Shaashada gariir ee ciidda Quartz waa nooc caan ahshaashad gariir rotary qalabka.Waxa iska leh qalabka wasakhaynta iftiinka.Waxaa loo isticmaali karaa 1-5 lakab isku mar.Qalabku wuxuu leeyahay sifooyin cabbir yar,wax yarbannaane shaqo, buuq yar, hufnaan sare, beddelka shaashadda ku habboon, qaab-dhismeed si buuxda u xiran, iwm.Waxaa si weyn loo isticmaalaa 0-400 mesh qalalan, qoyan, fiican, qallafsan,iftiin oo culusbudo,iyo granules si fudud ayaa loo baari karaa, iyo 0-600 oo walxaha dareeraha ah ee mesh si fudud ayaa loo sifeyn karaa.

Mabda'a shaqada ee shaashadda gariirka ciidda quartz:

Shaashadda gariirta ciidda quartz waxay isticmaashaa matoor gariir toosan oo ah isha kicinta, waxaana dhaqdhaqaaqa wareega loo rogaa dhaqdhaqaaq saddex-geesood ah oo toosan, toosan oo janjeera iyada oo loo marayo miisaannada eccentric ee darafyada sare iyo hoose ee matoorka gariirka, waxaana lagu kala qaadaadusha shaashadda eeshaashad gariir rotary; Geli qalabka iyada oo loo marayo dekedda quudinta.Marka loo eego shuruudaha baarista ee agabyada kala duwan, alaabada waxaa lagu baari karaa 1-5 lakab oo muraayado bir ah oo leh nambaro kala duwan oo mesh ah.Inta lagu jiro habkan, kubbadda boodboodka silikoonkawaayonadiifinta hoosteeda muraayadaha lakab kasta waxay si joogto ah u garaacdaa shaashadda iyada oo loo marayo gariir joogta ah, si walxaha lakabka sare ee shaashadda si habsami leh loogu baaro shaashadda, oo si wax ku ool ah u xalliso dhibaatada xannibaadda walxaha.Ka dib markii shabagga laga soo saaro dekedda laga sii daayo lakab kasta, ujeedada baaritaanka iyo ka saarista wasakhda ama shaandhaynta iyo qiimeynta ayaa ugu dambeyntii la xaqiiqsaday.

Waqtiga boostada: Nov-05-2022