Lehlabathe la quartz ke thepa ea bohlokoa ea lirafshoa tsa indasteri, thepa e kotsi e seng lik'hemik'hale,e lenge sebelisoa haholo ka khalase, ho lahla, lirafshoa&thepa refractory, smelting ferrosilicon, metallurgical flux, metallurgy, kaho, indasteri ea lik'hemik'hale, polasetiki, rabara, abrasives le liindasteri tse ling.al thepa.Lehlabathe la quartz hangata ke mofuta oa sefahla sa metsi se entsoeng ka ore ea tlhaho ea quartz, e silakanngoang, ea hlatsuoa, ea omisoa le ho hlahlojoa habeli.

Tlhahiso e omileng ea lehlabathe la quartz, lisebelisoa tse ka sehloohong liskrini se thothomelangbakeng salehlabathe la quartz, mochini o kokotang lejoe, crusher joalo-joalo.Mokhoa oa theknoloji ke hore majoe a majoe a quartz a fetoloa majoe a manyane ka mochini o kokotang lejoe, ebe lejoe le sebetsoa ke pulverizer, ebe joale.sefa ke askrine e sisinyehang.Ts'ebetsong ea ho hlahloba, tšepe e tlosoa ka ho sebelisa magnet bar le makenete, ebe ho paka ho phethoa ebe ho kenngoa polokelong.

Mokhoa oa tlhahiso ea lehlabathe la quartz

1.Ho sebetsa ka thata: (ka kakaretso 1-0.5mm, 0.5-0.1mm e ka lokisoa)

Khetha merafo ea lehlabathe ea quartz e nang le boleng bo botle bakeng sa merafo ea pele;lehlabathe la quartz le epiloeng le qala ho siloa ka sesila sa mohlahare, 'me lisebelisoa tse sithabetseng li fetisetsoa hosekirini se thothomelangbakeng sa tlhahlobo ea mantlha ka lebanta la conveyor, 'me likaroloana tse kholo li khutlisetsoa mehlahareng.Crusher e sebelisetsoa ho senya ka bobeli, 'me likaroloana tse nyenyane li tsamaisoa ke conveyor ea lebanta ho ea ho rolara bakeng sa ho sithabela ha bobeli.Lehlabathe la quartz le pshatlehileng ke "roller crusher" le romelloa ho hlahlojoa hantlesekirini se thothomelangbakeng sa ho hlahloba le ho hlophisa.

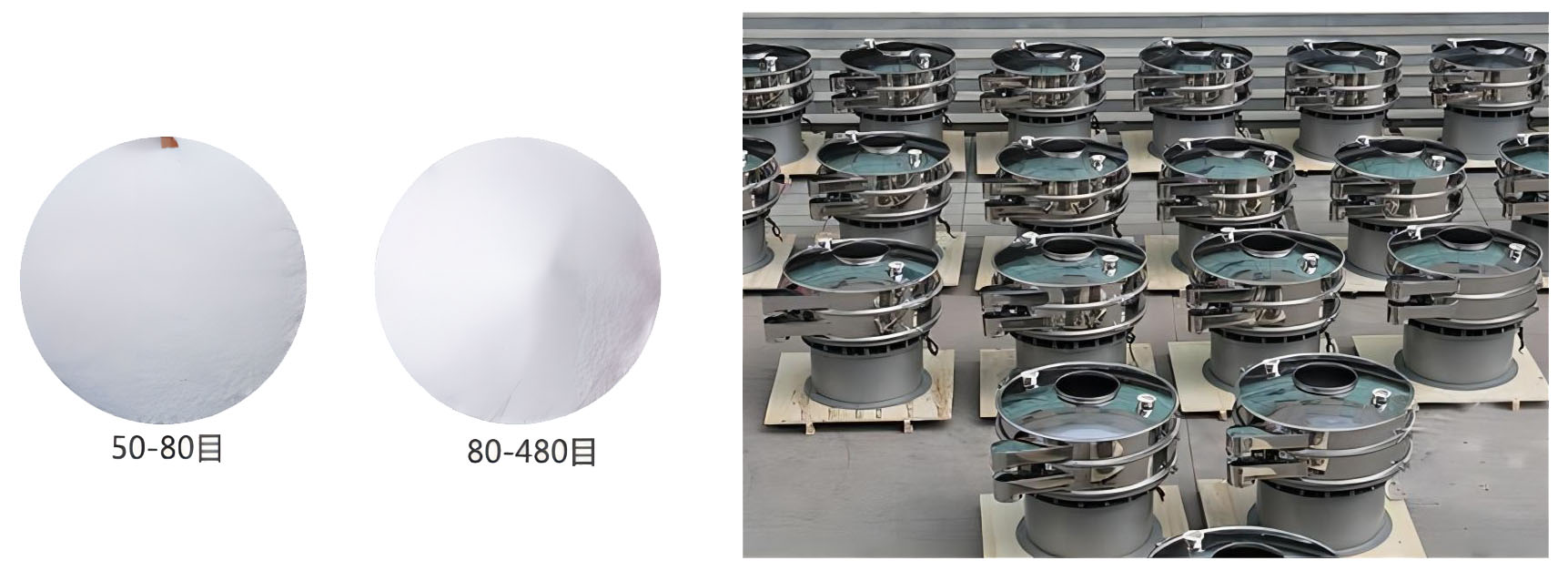

2.Ts'ebetso e ntle: (50-480 mesh)

Lehlabathe la quartz le entsoeng ka mahoashe la limaraka tsa 1-0.5mm le 0.5-0.1mm le ka sisinngoa le ho siloa ka leloala le thothomelang/leloala le thothomelang.Ka mor'a ho sila, e ka sieved kaskrine ea ultrasonic vibrating kapa skrine ea lehlabathe la quartz ho lokisa 100 -300 mesh phofo e ntle;haeba u batla ho finyella ho sila hamonate, leloala la Raymond le sebetsang hantle ka kakaretso le sebelisetsoa ho sila, 'me ha ho hlokahale ho sefa phofo.Leloala la Raymond ka kakaretso le na le mochini o hlahlobang.Beha boitsebisoka har'a mohlahlobi oa boemo bo felileng ho lokisa lihlahisoa tse 300-500 tsa mesh tse felileng.

Quartz sand vibrating screen ke mofuta o tloaelehilengskrine ea rotary vibrating thepa.Ke ea thepa ea ho tlosa litšila tse bobebe.E ka sebelisoa ka mekhahlelo e 1-5 ka nako e le 'ngoe.Thepa e na le litšobotsi tsa boholo bo nyane,nyanesebakae mosebetsi, lerata le tlaase, ts'ebetso e phahameng, ho fetola skrine e loketseng, mohaho o koaletsoeng ka ho feletseng, joalo-joalo. E ka finyella litlhoko tse sa tšoaneng tsa ho hlahloba phofo le likaroloana le litlhoko tsa ho hloekisa metsi, 'me e ka etsa tlhahlobo e ntle, ho tlosa litšila, ho hlophisa le ho hlahloba lisebelisoa tse ling.E sebelisoa haholo ho 0-400 mesh e omileng, e metsi, e ntle, e thata,kganya le boimaphofo,'me li-granules li ka hlahlojoa habonolo,' me lisebelisoa tsa 0-600 mesh slurry li ka hloekisoa habonolo.

Molao-motheo oa ts'ebetso oa skrine ea "quartz" e sisinyehang ea lehlabathe:

Skrine se sisinyehang sa lehlabathe la quartz se sebelisa enjene ea vibration e otlolohileng e le mohloli oa ho hlasimolla, 'me motsamao oa rotary o fetoloa motsamao o otlolohileng, o otlolohileng le o sekametseng mahlakoreng a mararo ka boima ba eccentric pheletsong e kaholimo le e tlase ea enjene ea vibration, mme e fetisetsoa hosefahleho sa skrine saskrine ea rotary vibrating; Kenya lisebelisoa ka koung ea phepelo.Ho ea ka litlhoko tsa tlhahlobo ea lisebelisoa tse fapaneng, lisebelisoa li hlahlojoa ke likarolo tse 1-5 tsa li-skrini tse lohiloeng tsa tšepe tse nang le linomoro tse fapaneng tsa mesh.Nakong ea ts'ebetso ena, bolo ea silicone bouncingbakeng saHo hloekisa ka tlas'a li-skrini tsa lera le leng le le leng ho tsoela pele ho otla skrine ka ho sisinyeha ha maqhubu, e le hore boitsebiso bo ka holimo ho skrine bo ka hlahlojoa hantle ka skrine, 'me ka katleho bo rarolle bothata ba ho thibela thepa.Ka mor'a hore letlooa le lokolloe boema-kepe ba ho tsoa sebakeng se seng le se seng, sepheo sa ho lekola le ho tlosa litšila kapa ho sefa le ho hlopha sea phethahala.

Nako ea poso: Nov-05-2022