Quartz sand is an important industrial mineral raw material, non-chemical dangerous goods, which is widely used in glass, casting, ceramics & refractory materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industrial materials. Quartz sand is generally a kind of water treatment filter material made of natural quartz ore, which is crushed, washed, dried and screened twice.

Dry production of quartz sand, the main equipment are vibrating screen for quartz sand, stone knocking machine, crusher and so on. The technological process is that the quartz stone ore is processed into smaller stones by a stone knocking machine, the stone is then processed by a pulverizer, and then sieved by a vibrating screen . In the screening process, the iron is removed by using the magnet bar and the magnet, and then the packing is completed and put into storage.

The production process of quartz sand

1. Rough machining: (generally 1-0.5mm, 0.5-0.1mm can be prepared)

Select quartz sand mines with good quality for preliminary mining; the mined quartz sand is first crushed by jaw crusher, and the crushed materials are conveyed to the linear vibrating screen for primary screening through the belt conveyor, and the large particles are returned to the jaws. The crusher is used for secondary crushing, and the small particles are transported by the belt conveyor to the roller crusher for secondary crushing. The quartz sand crushed by the roller crusher is sent to the fine screening linear vibrating screen for screening and classification.

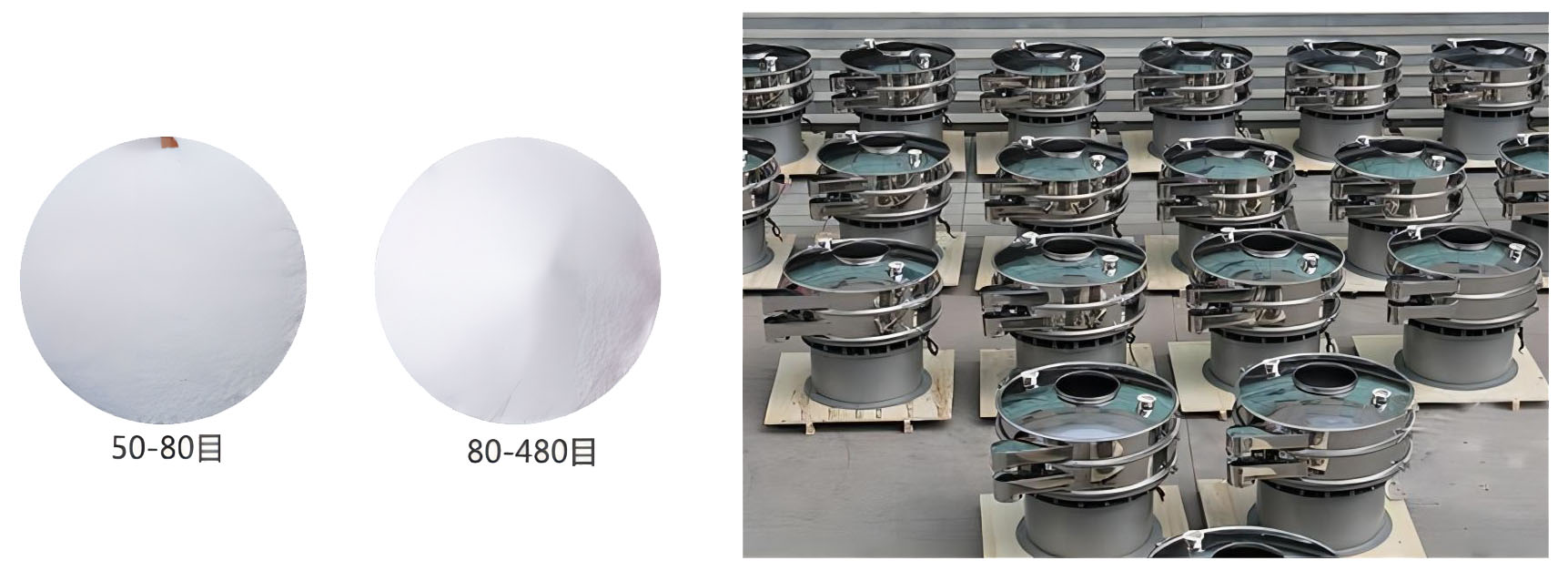

2. Fine processing: (50-480 mesh)

The coarsely processed quartz sand of 1-0.5mm and 0.5-0.1mm grades can be vibrated and ground by a vibrating mill/vibrating rod mill. After grinding, it can be sieved with an ultrasonic vibrating screen or a quartz sand vibrating screen to prepare 100 -300 mesh fine powder; if you want to achieve finer grinding, a high-efficiency Raymond mill is generally used for grinding, and there is no need to sieve the powder. The Raymond mill is generally equipped with an analyzer. Put the material into the finished-grade analyzer to prepare 300-500 mesh finished products.

Quartz sand vibrating screen is a kind of common rotary vibrating screen equipment. It belongs to light impurity removal equipment. It can be used in 1-5 layers at the same time. The equipment has the characteristics of small size, little space occupation, low noise, high efficiency, convenient screen changing, fully enclosed structure, etc.. It can meet various powder and particle screening needs and liquid filtration needs, and can perform fine screening, impurity removal, grading and other screening operations on materials. It is widely used in 0-400 mesh dry, wet, fine, rough, light and heavy powder, and granules can be easily screened, and 0-600 mesh slurry materials can be easily filtered.

The working principle of quartz sand vibrating screen:

The quartz sand vibrating screen uses a vertical vibration motor as the excitation source, and the rotary motion is converted into horizontal, vertical and inclined three-dimensional motion through the eccentric weights at the upper and lower ends of the vibration motor, and is transmitted to the screen surface of the rotary vibrating screen ; Enter the equipment through the feeding port. According to the screening requirements of different materials, the materials are screened by 1-5 layers of metal woven screens with different mesh numbers. During this process, the silicone bouncing ball for cleaning under the screens of each layer continuously hits the screen through frequency vibration, so that the material on the upper layer of the screen can be smoothly screened through the screen, and effectively solve the problem of material blocking. After the net is discharged from the discharge port of each layer, the purpose of screening and removing impurities or filtering and grading is finally realized.

Post time: Nov-05-2022