1.Ukuphakelwa okufanayo: inani lokuphakelwa kufanele lihlangabezane nokucutshungulwa kwemishini.Ukuphakelwa kwempahla eningi ngesikhathi esisodwa kuzokhinyabeza ukunyakaza okuvamile kwento engaphezulu kwesikrini, okungeke kwenze kalula nje kuphela inetha lesikrini ukuthi likhathale futhi lixege, kodwa futhi kunciphise kakhulu umthamo wokubamba izinto.Ukunikeza inani elikhulu lezinto ngesikhathi esisodwa kuzokwandisa ngokuzumayo umthwalo we-vibration motor egijima ngokungalingani, okubangela ukulimala kwemoto nokunciphisa impilo yemoto.

2.Indlela yokuphakela enamandla anamandla kumele ifakwe i-buffer hopper.Okubalulekile kuthinta ngokuqondile indawo enezikhala, engadli nje kuphela amandla ajabulisayo akhiqizwa umthombo wokudlidliza, kodwa futhi idala kalula umonakalo endaweni enezikhala nokukhathala kwesikrini, okuthinta okukhiphayo nokuhlolwa nokuhlunga.izinga.

3.Uma into yokuhlola igqwala, sicela uyihlanze ngesikhathi ngemuva kokusetshenziswa.

4.Sicela ubuke inetha esebenzayo njalo ukuze ubone ukuthi iyaxega yini, sicela uqinise inetha futhi.

5.Uma isikrini sitholakala ukuthi sonakele, kufanele simiswe ngokushesha ukuze kufakwe isikrini esisha;

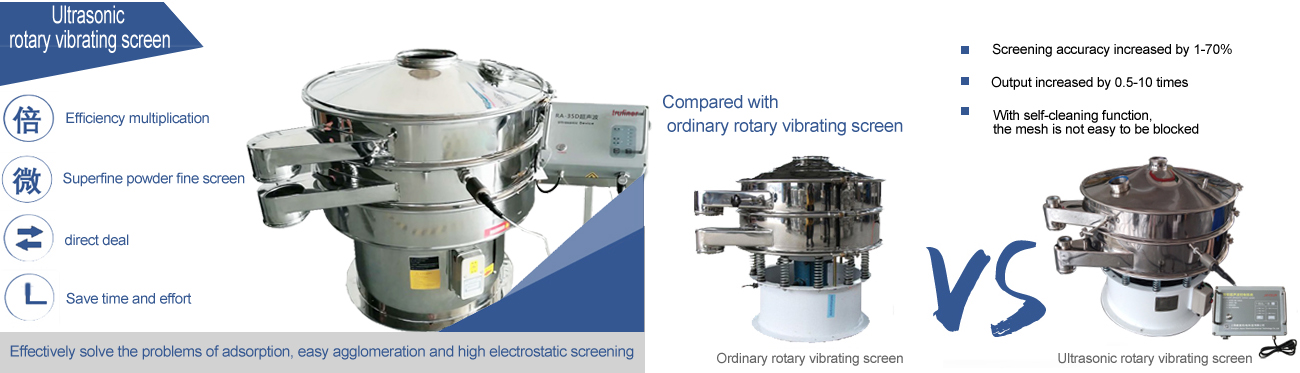

Ukuqhathaniswa kwezinzuzo zesikrini sokudlidliza se-ultrasonic kanye nesikrini sokudlidliza esijwayelekile

Isikrini sokudlidliza se-ultrasonic siyidivayisi yokuguqula amandla e-ultrasonic enamathiselwe endaweni yokusebenza yesikrini esijwayelekile esizungezayo, okungukuthi, amandla kagesi angu-220V, 50Hz aguqulwa abe ngu-30±1KHz, ukuze kugcinwe izimbobo zesikrini zingavinjwanga futhi kuzuzwe injongo. yokuhlola nokuhlanza., ifaneleka kakhulu ekuhlolweni kwempushana ecolekile enevelu ephezulu.Ngaphezu kwalokho, idinga ukuchazwa ngokuningiliziwe ukuthi i-ultrasonic vibration wave (igagasi lomshini) elinamathiselwe esikrinini livumela impushana ukuthi ithole ukusheshisa okukhulu kwe-ultrasonic, ngaleyo ndlela ivimbele ukunamathela, ukungqubuzana, Ukuvimbela izici ezifana nokulinganisa nokushada kungathuthukisa ukusebenza kahle kokuhlolwa. kanye nokusebenza kahle kokuhlanza inetha.

Isikrini esijwayelekile sokudlidliza se-ternary singahlola izinto ezihlukene eziyimpuphu, futhi umphumela wokuhlola muhle.Kodwa-ke, lapho kusefa i-silicon carbide, i-brown corundum, i-corundum emhlophe, i-cobalt powder, ufulawa, impushana yokwelapha, njll., ingahlungwa ngokuya ngesimiso sokusebenza, kodwa ayikwazi ukuhlangabezana nezidingo mayelana nomthamo wokucubungula nokunemba kwe-sieving. .Enqubweni yokusefa, umshini wesikrini ojwayelekile udlidliza nje ngomshini.Uma isikrini somshini wesikrini sivinjwe yi-mesh, umshini wesikrini ojwayelekile awukwazi ukuxazulula inkinga, futhi okukhiphayo ngeke kuthuthukiswe.Isikrini sokudlidliza se-ultrasonic singavele sihlangabezane nale mfuneko.

Ngakho-ke, izinzuzo zesikrini sokudlidliza se-ultrasonic kanye nesikrini sokudlidliza esijwayelekile zimi kanje:

1.Ukunemba okuhlukile kokuhlola: ngenxa yesistimu yokuhlola ye-ultrasonic ehlomile, indawo yesikrini ine-high-frequency kanye ne-low-amplitude ultrasonic vibration wave ngenkathi yenza ukunyakaza kwe-three-dimensional, ukuze impahla imiswe endaweni yesikrini endaweni ephansi. ukwandisa ukunemba kokuhlolwa.Ukunemba kokuhlolwa kungafinyelela ngaphezu kuka-95%, kuyilapho ukunemba kokuhlolwa kwesikrini esindindizelayo esivamile ngokuvamile kucishe kube ngu-60% -70%;

2. Ukuxazulula ngokuphumelelayo inkinga yokuvimbela inetha: idivayisi yokuhlanza inetha yesikrini esijwayelekile sokudlidliza yibhola elishayayo, elingahlanza izinto ezibonakalayo ze-granular, kodwa ngenxa yezinto ezibonakalayo ze-powder noma ezinye izinto ezinezakhiwo ezikhethekile, umphumela wokuhlanza inetha akubonakali, futhi isikrini sokudlidliza se-ultrasonic sinokudlidliza kwe-ultrasonic.Ukuba khona kwamagagasi okudlidliza, ngakho indawo yesikrini ingahlanzwa ngempumelelo ukuze kuzuzwe injongo yokungavimbi isikrini;

3.Okukhipha okuhlukile: Ngenxa yokufakwa kwesistimu yokuhlola i-ultrasonic, ukukhishwa kwesikrini sokudlidliza kwe-ultrasonic izikhathi ezingu-2-10 kunesibuko esivamile sokudlidliza lapho kuhlolwa impushana, i-granule nezinto eziludaka.

Isikhathi sokuthumela: Mar-17-2022