1.Ciyar da Uniform: adadin ciyarwa ya kamata ya dace da sarrafa kayan aiki.Yawan ciyar da kayan abu a lokaci ɗaya zai hana al'ada motsi na kayan a kan fuskar allo, wanda ba kawai zai sa ragamar allon ya gaji da sassauta ba, amma kuma yana rage ƙarfin sarrafa kayan.Ba da adadi mai yawa na kayan aiki a lokaci ɗaya ba zato ba tsammani yana ƙara nauyin motar girgizar da ke gudana ba daidai ba, yana haifar da lalacewa ga motar da kuma rage rayuwar motar.

2.Hanyar ciyarwa tare da ƙarfin tasiri mai karfi dole ne a sanye shi da buffer hopper.Abun yana tasiri kai tsaye a saman raga, wanda ba wai kawai yana cinye ƙarfi mai ban sha'awa da tushen girgizar ya haifar ba, amma kuma yana haifar da lalacewa cikin sauƙi a saman raga da gajiyawar allo, wanda ke shafar fitarwa da nunawa da tacewa.inganci.

3.Idan kayan nunawa yana da lalacewa, don Allah a tsaftace shi a cikin lokaci bayan amfani.

4.Da fatan za a kalli gidan yanar gizon aiki akai-akai don ganin ko ta yi sako-sako, da fatan za a sake ƙara ƙarar ragar.

5.Idan an gano allon ya lalace, yakamata a dakatar da shi nan da nan don maye gurbin sabon allon;

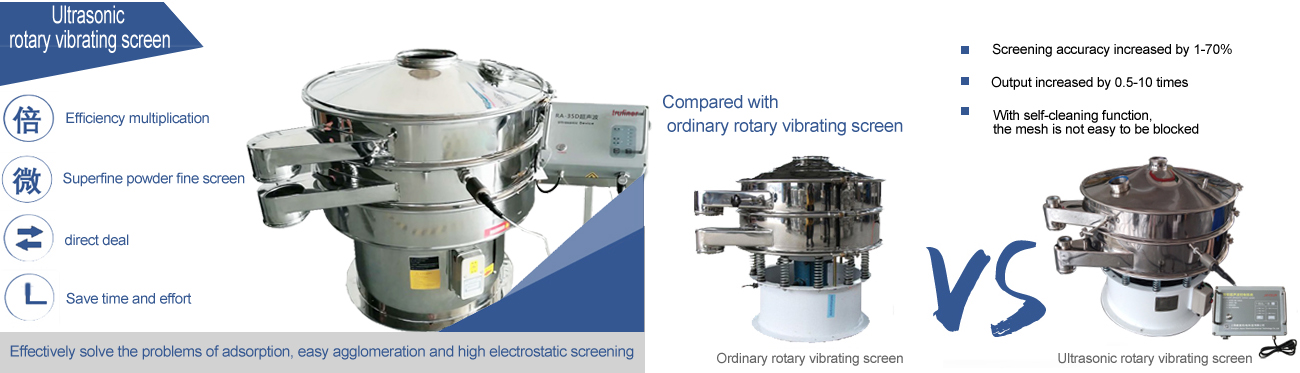

Kwatanta abũbuwan amfãni daga ultrasonic vibrating allo da talakawa vibrating allo

A ultrasonic vibrating allo ne ultrasonic makamashi hira na'urar da aka haɗe zuwa aiki surface na talakawa Rotary vibrating allo, wato, da 220V, 50Hz wutar lantarki da aka tuba zuwa 30± 1KHz, don kiyaye allo ramukan unobstructed da cimma manufar. na nunawa da tsaftacewa., mafi dacewa don nunawa na babban foda mai daraja.Bugu da ƙari, yana buƙatar bayyana dalla-dalla cewa motsin motsin motsi na ultrasonic (wave na inji) wanda aka haɗe zuwa allon yana ba da izinin foda mai kyau don karɓar babban haɓakar ultrasonic, ta haka ya hana mannewa, gogayya, Abubuwan toshewa kamar matakin daidaitawa da wedging na iya inganta ingantaccen nunawa. da net tsaftacewa yadda ya dace.

Allon jijjiga na yau da kullun na iya duba nau'ikan kayan foda, kuma tasirin nuni yana da kyau.Duk da haka, a lokacin da sieving wasu silicon carbide, launin ruwan kasa corundum, farin corundum, cobalt foda, gari, magani foda, da dai sauransu, shi za a iya sieved cikin sharuddan aiki ka'idar, amma shi ba zai iya saduwa da bukatun cikin sharuddan aiki iya aiki da sieving daidaito. .A cikin tsarin sieving, injin allo na yau da kullun yana jijjiga na inji kawai.Lokacin da aka toshe allon na'urar ta hanyar raga, injin allo na yau da kullun ba zai iya magance matsalar ba, kuma fitarwar ba za ta inganta ba.Allon jijjiga ultrasonic na iya cika wannan buƙatu kawai.

Saboda haka, abũbuwan amfãni daga ultrasonic vibrating allo da talakawa vibrating allo ne kamar haka:

1.Different dubawa daidaito: saboda sanye take da ultrasonic screening tsarin, allon surface yana da wani high-mita da kuma low-amplitude ultrasonic vibration kalaman yayin da yin uku-girma motsi, don haka da abu da aka dakatar a kan allon surface a wani low tsawo. don ƙara daidaiton nunawa.Daidaiton nunawa zai iya kaiwa sama da 95%, yayin da daidaiton nunin allo na girgizawa gabaɗaya kusan 60% -70%;

2.Effectively warware matsalar tarewa da net: da net tsaftacewa na'urar na talakawa vibrating allo ne a bouncing ball, wanda zai iya tsaftace granular kayan, amma ga madaidaicin foda kayan ko wasu kayan da musamman Properties, da net tsaftacewa sakamako ne ba a bayyane ba, kuma allon jijjiga na ultrasonic yana da vibration na ultrasonic.Kasancewar raƙuman girgiza, don haka ana iya tsabtace fuskar allo yadda ya kamata don cimma manufar rashin toshe allon;

3.Different fitarwa: Saboda shigarwa na ultrasonic nunawa tsarin, da fitarwa na ultrasonic vibrating allo ne 2-10 sau na talakawa vibrating allo lokacin nunawa foda, granule da slurry kayan.

Lokacin aikawa: Maris 17-2022