I-pneumatic vacuum feedersisixhobo sokuhambisa umbhobho ongenathuli, ovaliweyo, osebenzisa ukufunxa ivacuum ukuthutha imathiriyeli yomgubo.Isixhobo sisebenzisa ukuhluka koxinzelelo lomoya phakathi kwe-vacuum kunye nendawo ejikelezileyo ukwenza ukuhamba komoya kumbhobho ukuqhuba ukuhamba kwezinto ezinomgubo, ngaloo ndlela ukugqiba ukuhanjiswa kwezinto.

Okwangoku, uninzi lwemithombo yevacuum ye-pneumatic zisebenzisa iimpompo zokufunxa umoya njengemithombo yokufunxa.Izinto ezikwisikhongozeli zingathunyelwa ngokuthe ngqo kumxube, ireactor, hopper, tablet press, bag, vibrating screen, granulator, granulator emanzi, igranulator eyomileyo, njl.

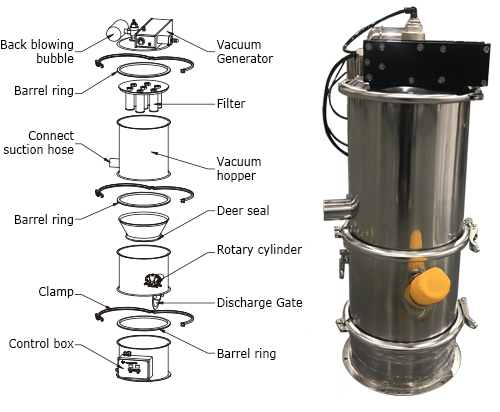

Emva kweqhosha elithi "ON/OFF" lei-pneumatic vacuum feeder, umoya ocinezelweyo ungena kwimpompo yokucoca.Ngokutyhala kwe-cylinder, ivalve yokuphuma ye-hopper ivaliwe ukwenza i-vacuum state kwi-hopper.Umatshini wokufunxa wenza ukuhamba komoya kwi-vacuum.Izinto ezihanjiswayo zigqithiselwa kwi-vacuum hopper ngombhobho phantsi kwesenzo sokuhamba komoya.

Ngexesha elithile, umoya ocinezelweyo uvaliwe, kwaye ipompo yokucoca i-pneumatic ayikwazanga ukuvelisa i-vacuum.Ngelo xesha, i-valve yokuphuma ye-hopper ivuliwe phantsi kwe-push ye-cylinder yomoya, i-vacuum ye-vacuum feeder iyanyamalala, kwaye izinto ngokuzenzekelayo zingena kwi-port yokufumana kwi-outlet.Kwangaxeshanye, umoya ocinezelweyo kwingxowa yomoya uvuthelwa umva kwiscreen sokucoca, kwaye isihluzi sicocwa ngokuzenzekelayo.

Emva kwexesha elithile, umoya ocinezelweyo uqaliswe kwakhona, ipompo yokucoca i-pneumatic ivelisa i-vacuum, i-port yokukhupha ivaliwe, i-vacuum feeder feeder kwakhona, kwaye izixhobo zithunyelwa ngokuqhubekayo kwisixhobo sokufumana.

Ngelizwi, oku ngasentla ngumgaqo wokusebenza wei-pneumatic vacuum feeder.Yamkela indlela yokuhambisa evaliweyo.Le ndlela yokuthutha inokuphelisa ukungcoliseka kothuli kokusingqongileyo, iphucule indawo yokusebenza, inciphise ukungcoliseka kokusingqongileyo kwendalo yendalo kunye nabasebenzi kwizinto eziluhlaza, kwaye iphucule inqanaba lokucoceka.Imveliso ithuthwa ngombhobho, igubungela indawo encinci, kwaye inokugqiba ukuthuthwa komgubo kwindawo emxinwa;Ngokukodwa, akukhawulelwanga ngumgama omde kunye nomgama omfutshane.Ukuhanjiswa kwevacuum nako kunokunciphisa amandla okusebenza kunye nokuphucula ukusebenza kakuhle.

I-vacuum feeder ikakhulu isebenzisa umahluko woxinzelelo lomoya ngaphakathi nangaphandle kwezixhobo zokuthutha izinto.Ukusebenza ngamandla okufunxa, kunokuthutha umgubo okanye imathiriyeli yegranular.I-pneumatic vacuum feeder iye yaba sisixhobo esiza kusetyenziswa ngamashishini amakhulu.Nangona kunjalo, amashishini anokufumanisa ukuba izixhobo azikwazi ukufunxa imathiriyeli kwinkqubo yokusetyenziswa.Siyintoni isizathu soko?

Isizathu soku-1: Ipompo ye-pneumatic yonakalisiwe

Ukuba kufunyaniswe ukuba i-pneumatic vacuum feeder ayikwazi ukufunxa imathiriyeli, ikakhulu kuba impompo yomoya kwisixhobo yonakele.Emva kokuba isixhobo sonakaliswe, siya kukhokelela kwingxaki yokungakwazi ukufunxa izinto, ngakumbi ngenxa yoxinzelelo olungonelanga.Ngoko ke, kubalulekile ukujonga ipompo ye-pneumatic kwisixhobo sokuqala ukufumanisa ukuba isixhobo sonakalisiwe, kunye nokulungiswa kwangexesha okanye endaweni yayo.

Isizathu sesi-2: Ukusebenza ngendlela engafanelekanga

I-pneumatic vacuum feeder ineemfuno zokusebenza ezingqongqo kakhulu.Ukuba ukufakela okanye ukusebenza akuhambelani neemfuno ezihambelanayo, kuya kuba nefuthe elithile ngokuthe ngqo ekuhanjisweni kwezinto eziphathekayo, okuya kukhokelela kwimeko yokuba izinto azikwazi ukufunxa.Ngoko ke, ngexesha lenkqubo yokusebenza, ingqalelo kufuneka ihlawulwe kwakhona ekusebenziseni izixhobo ngokweenkcukacha ezichanekileyo.

Ayisiyiyo loo nto kuphela, kwizixhobo ze-pneumatic vacuum feeder, ukuba kukho iimpazamo ezithile kwisethingi yeparameter, iya kuchaphazela nefuthe lokusetyenziswa kwesixhobo.Ngoko ke, umsebenzisi kufuneka azame ukufumanisa izizathu ezithile, ukufumanisa ukuba zeziphi iingxaki ezibangela ukuba izixhobo zingaphumeleli ukufunxa izinto, kwaye emva koko zizisombulule ngokufanelekileyo.

Ixesha lokuposa: Oct-23-2022