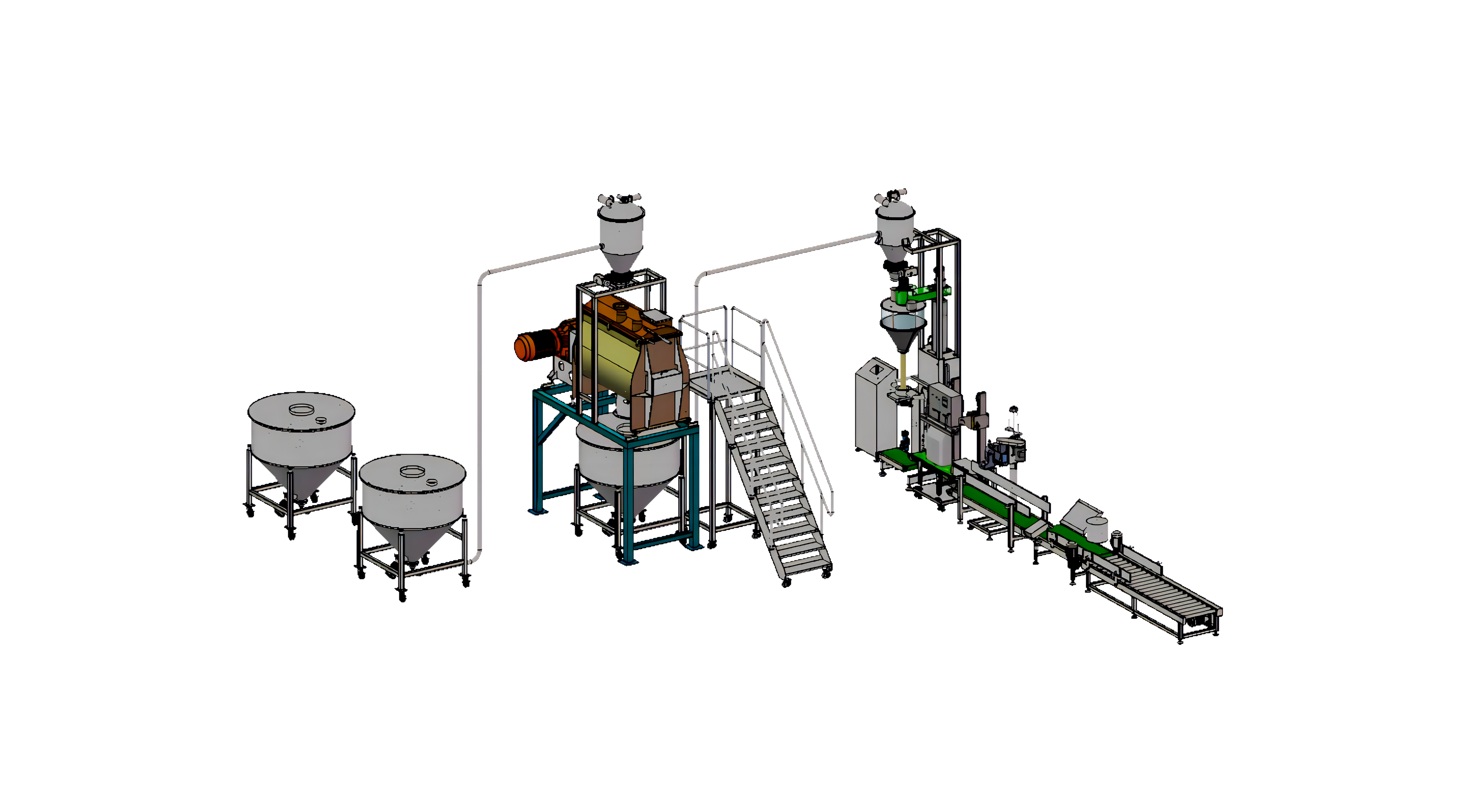

Powder Packaging Automatic Production Line

Working principle

Automatic feeding → dust-free lifting packaging machine (manual bagging) → weight selection and inspection scale → heat sealing machine → bag sewing → sorting and reversing → metal inspection→Storage

Main Features:

1. Product specifications: suitable for packaging of powder within 1-50KG ;

2. Packaging accuracy: 1-20KG, ≦±0.1-0.2%, >20KG, ≦±0.05-0.1%;

3. Power supply: 3P 380V 50Hz (can be customized according to customers’ needs)

4. Material: This production line is made of stainless steel, and all machine structures are designed in accordance with food hygiene standards.

5. The normal production of this production line requires 1-2 workers.

Equipment Advantages:

1. The system features automatic proportioning, feeding, packaging and conveying control of the PLC, which is small in size, high in precision and good in stability.

2. The complete batching system can control multiple scales at the same time, with a variety of material and control output (according to customers’ requirements);

3. The space layout is simple and compact, and the heights are orderly, which effectively saves the cost of space use;

4. The servo motor drives the tray to lift up and down, and the lifting speed can be set arbitrarily, and basically no dust is released to pollute the environment when charging.

5. The control screw is driven by a servo motor and a servo, with stable performance and high precision; Easy operation with PLC control, touch screen man-machine interface display;

6. All stainless steel structure; combined or open material box, very convenient to clean;

7. Pneumatic bag clamping device and can holding device are optional, to meet the requirements of canning and bagging;