China large capacity Plane Rotary Vibrating Screen Machine Manufacturer

Product introduction:

plane rotary screen is another new type of screening equipment developed by introducing foreign advanced technology. The machine has the advantages of reasonable design, simple structure, stable operation, fully closed structure, dust-free, anti blocking hole, anti sticking net and so on. Especially for urea screening with strong hygroscopicity, high viscosity, easy hole plugging and mesh sticking. Due to the principle of plane rotary motion, the dynamic static ratio of the equipment and the dynamic load of the foundation are effectively reduced. The equipment adopts a plane rotary vibrating screen to vibrate up and down, and there is an automatic cleaning equipment under the screen. Compared with the traditional linear screen, it improves the service life of the screen, has low noise and large screening area, and improves the efficiency from 93 ~ 95 to 98.5. It has a good popularization prospect. The plane rotary urea screening machine is mainly a new screening equipment developed for the screening of large urea, soda ash and quartz sand. It is also widely used in the screening operation of chemical industry, grain processing, refractory, building materials and other industries.

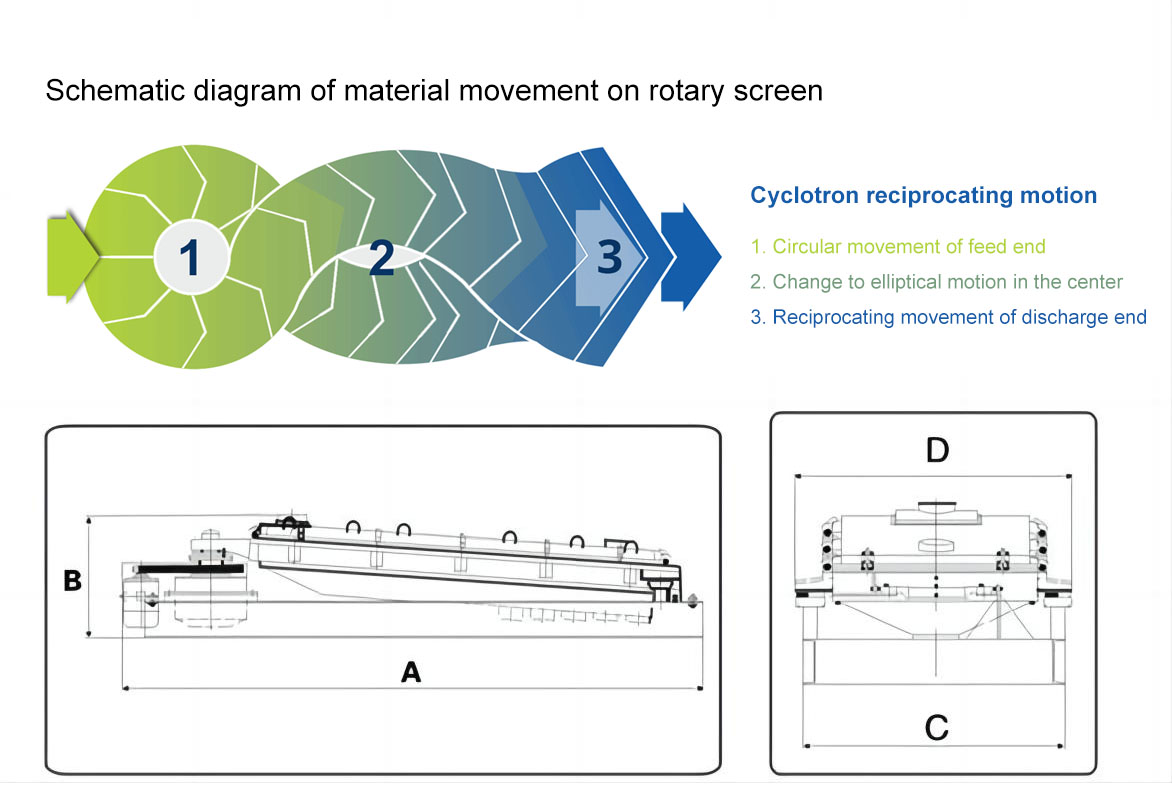

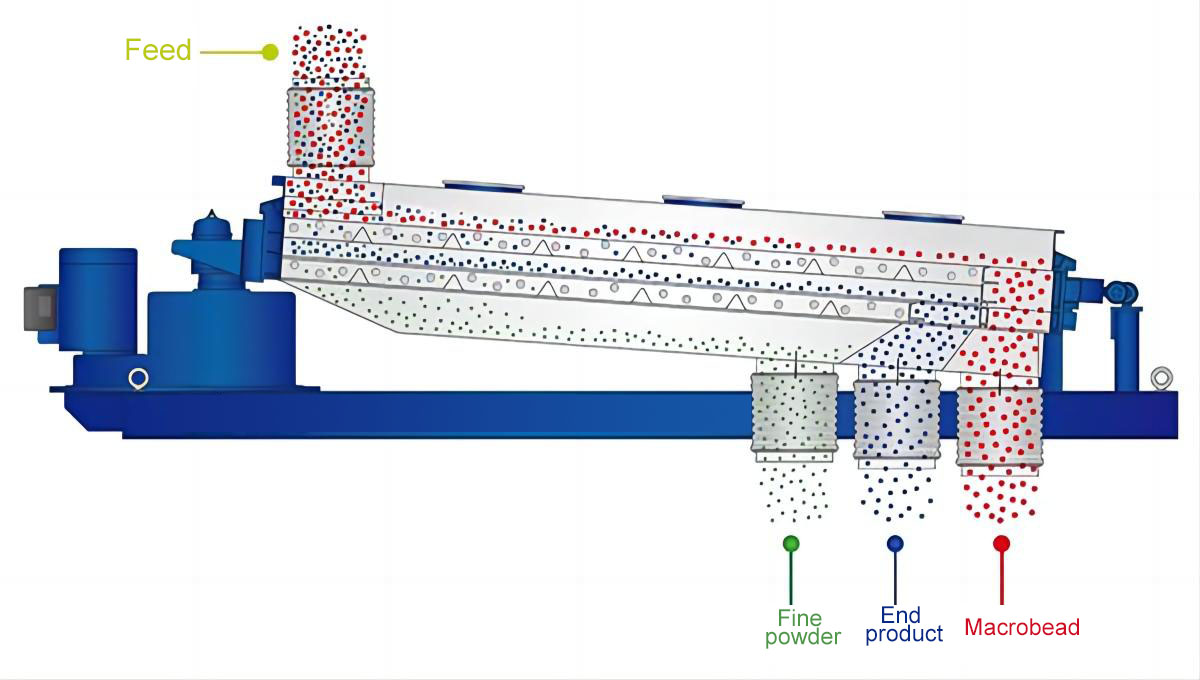

working principle:

From the motion track of the shaking body of the screen machine, that is, the screen box, the plane rotary screen is also known as the reciprocating screen. The vibration force generated by its driving device is an inertial force that changes regularly around the fixed axis. Its essence is the reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to the structural characteristics and working principle of rotary screen, its screen surface is generally arranged horizontally or slightly inclined. The principle is that the material will fall to the upper and lower screen holes after the screen passes through the screen, and the rotating force of the screen will be smaller than that of the lower screen box, so as to make the material fall to the upper and lower screen holes after the screen passes through the screen. The rotating force of the screen box is smaller than that of the lower screen, Finally complete the screening work.

Product features:

(1) The self-cleaning effect is excellent. Each layer of screen is equipped with screen anti blocking cleaning device without blocking the screen;

(2) The processing capacity is large, which reduces the powder content in the finished material, which is 10 times that of the ordinary sieve;

(3) no vertical vibration, long screen life (6-12 months).

(4) each layer of the screen is equipped with screen anti-blocking cleaning device. The screen does not block the holes and prolongs the operation cycle. The sifter continuously cleans the screen in working condition.

(5) because of the plane rotary principle, obviously improve the distribution state of the material, so as to improve the effective utilization rate of the screen surface, and finally improve the screening efficiency and reduce the powder content in the finished material.

(6) fully enclosed structure without dust pollution, improve the working environment of operating staff.

(7) The dynamic load on the foundation is very small, and the noise is very low.

Technical parameter:

|

Model |

Screen Surface Area(mm) |

Feeding Size (mm) |

Amplitude (mm) |

Frequency (r/min) |

Power (kW) |

Layer |

|

CF1224 |

1200X2400 |

<15 |

75-90 |

1450 |

3-5.5 |

1-3 |

|

CF1230 |

1200×3000 |

<15 |

||||

|

CF1236 |

1200×3600 |

<15 |

||||

|

CF1524 |

1500×2400 |

<15 |

||||

|

CF1530 |

1500X3000 |

<15 |

||||

|

CF1536 |

1500×3600 |

<15 |

||||

|

CF1830 |

1800×3000 |

<20 |

750 |

5.5-7.5 |

||

|

CF1836 |

1800×3600 |

<20 |

||||

|

CF1840 |

1800×4000 |

<20 |

||||

|

CF2040 |

2000×4000 |

<20 |

|

Model |

Effective screening area(m²) |

Power(KW) |

Screening angle(°) |

Layer number |

Rotation frequncy (r/min) |

screening box travel (mm) |

Overall dimensions (mm) |

|

CF-0.36 |

3.6 |

3 |

5-8 |

1-8 |

180-260 |

25-60 |

4442*1700*1917 |

|

CF-1236 |

4.32 |

4 |

5-8 |

1-8 |

180-260 |

25-60 |

4442*1900*1917 |

|

CF-1536 |

5.4 |

5.5 |

5-8 |

1-8 |

180-260 |

25-60 |

4442*2200*1917 |

|

CF-1836 |

6.48 |

7.5 |

5-8 |

1-8 |

180-260 |

25-60 |

4442*2500*1917 |

|

CF-2036 |

7.2 |

7.5 |

5-8 |

1-8 |

180-260 |

25-60 |

4442*2700*1917 |

Product Application

1. Chemical industry: resin powder, paint, washing powder, fine powder, paint, soda ash, lemon powder, rubber, plastic and so on.

2. Abrasive, ceramic industry: alumina, quartz sand, mud, spray soil particles.

3. Food industry: sugar, salt, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar and so on.

4. Paper industry: coating coatings, white mud, black and white liquid, waste liquid, paper liquid, waste water recovery.

5. Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder.